It’s a frustrating moment: you open your washing machine expecting clean, damp clothes, but instead, you find a sopping wet mess. Laundry day comes to a screeching halt when your washer won't spin, leaving you with a heavy, waterlogged problem.

The good news? A washer that won't spin is often a simple fix you can sort out in minutes, no tools required. More often than not, the culprit is something straightforward like an unbalanced load or the wrong cycle setting. This expert guide will walk you through easy checks, common part failures, and tell you when it’s time to call a pro.

Initial Checks When Your Washer Won't Spin

Before worrying about broken parts, start with the basics. These simple, tool-free checks solve the vast majority of spinning problems. Modern washers have sensors that will stop a cycle to prevent damage, so ruling out these common triggers is the best place to start.

Usually, the issue isn't a mechanical failure but a simple operational hiccup. A closer look at your laundry load and the machine’s settings can get things spinning again.

Quick Troubleshooting Checklist For a Non-Spinning Washer

Before diving deeper, run through these common-sense checks. They are the most frequent reasons a washer stops spinning and take only a few minutes to verify.

| Check | What to Look For | Quick Fix |

|---|---|---|

| Cycle Setting | Accidental selection of "No Spin," "Delicate," or "Hand Wash" cycles. | Select and run a "Drain & Spin" or "Spin Only" cycle. |

| Power Supply | Is the plug loose? Has the circuit breaker tripped? | Ensure the plug is secure. Check your breaker box and reset if needed. |

| Electronic Glitch | Minor errors in the control board from power fluctuations. | Unplug the washer for 5 minutes, then plug it back in to perform a hard reset. |

| Load Balance | Clothes, towels, or bedding bunched up on one side of the drum. | Open the lid and manually redistribute the wet items evenly. |

| Bulky Items | A single heavy item (duvet, bathmat) is washing alone. | Add a few smaller towels to help balance the weight distribution. |

These steps resolve most issues without needing to pull the machine out or grab a single tool. If you've tried all of these and the drum still won't spin, it's time to investigate some common mechanical causes.

Confirm Your Cycle Settings

It sounds almost too obvious, but it happens more than you’d think. Some wash cycles are specifically designed to spin very slowly—or not at all—to protect delicate fabrics.

- Delicate or Hand Wash Cycles: These settings use a gentle, slow spin by design. Your clothes will naturally come out much wetter than they would on a normal cycle.

- No Spin or Drain Only: Many washers have a dedicated "No Spin" option. If it was selected by mistake, the machine will drain out the water but won't ramp up to spin the clothes.

If you suspect this is the problem, the solution is easy: just run a separate "Drain & Spin" cycle to wring out all that excess water.

Check the Power Connection and Reset

Even a brief power flicker can scramble a washer's electronic brain, causing it to halt mid-cycle.

First, make sure the washing machine is plugged firmly into the wall socket, as heavy vibrations can sometimes work it loose. Next, check your home's circuit breaker to see if it has tripped.

Pro Tip: If the power connection is solid, try a hard reset. Unplug the washer from the wall, wait a full five minutes, and then plug it back in. This simple step can clear out minor electronic glitches and often gets the machine working again instantly.

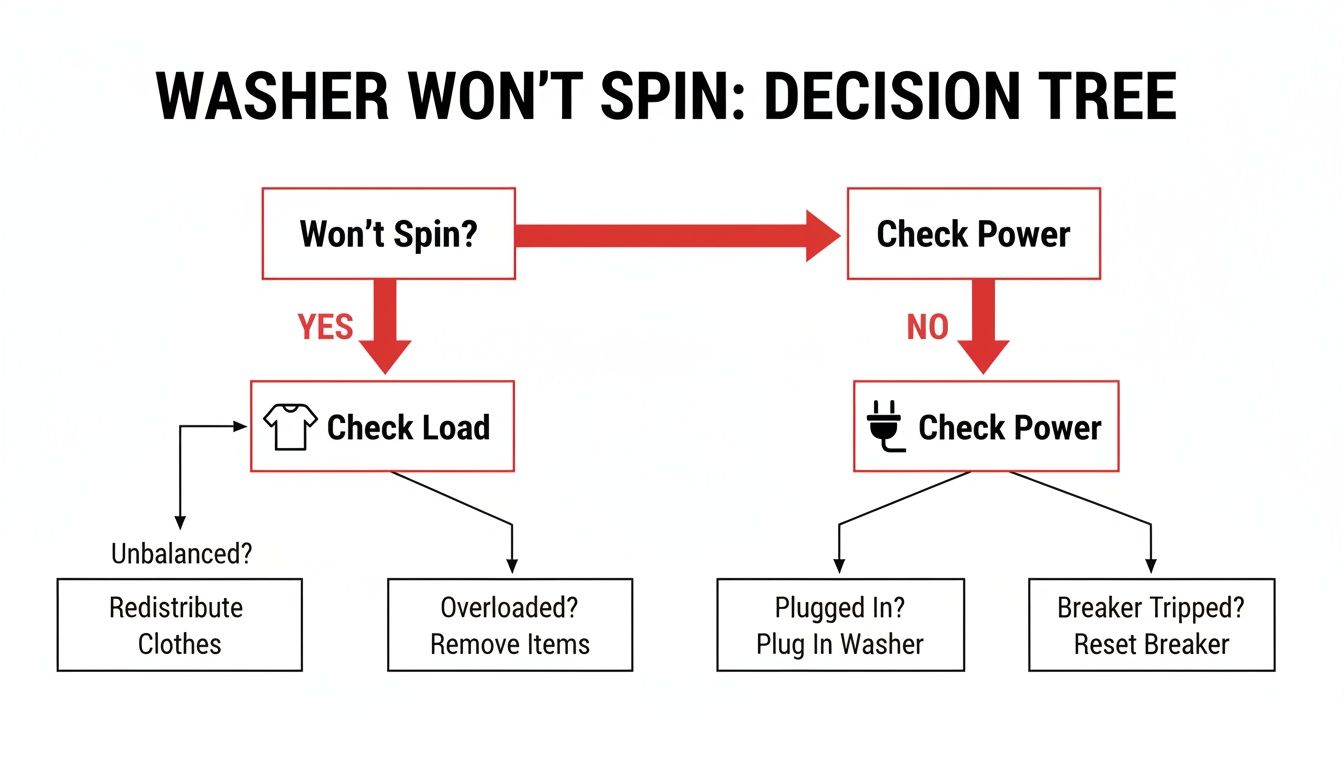

This decision tree helps visualize the first two things you should always check.

As the guide shows, checking your load balance and power supply are the most critical first moves.

Balance the Laundry Load

By a long shot, the most frequent reason a washer refuses to spin is an unbalanced load. When laundry clumps together on one side of the drum, sensors shut down the spin cycle to prevent the machine from violently shaking itself apart. This happens all the time when washing a single bulky item like a duvet, a heavy bathmat, or just a few water-logged towels.

To fix it, just open the lid and rearrange the wet items evenly around the drum. If you were washing one big, heavy thing, try adding a few smaller towels to help balance it out. Close the lid and restart the spin cycle.

A balanced load lets the drum get up to speed smoothly. Keep in mind, sometimes a clogged drain pump can also prevent the spin cycle from starting; you can learn more about how to clean a washing machine filter in our detailed guide.

Okay, you’ve double-checked the settings and made sure the laundry is balanced, but the drum still won’t budge. Now it’s time to investigate the machine’s mechanical parts. These are the components that do the real heavy lifting, and just like any hard-working part, they can wear out over time. Figuring out what went wrong is usually a simple process of elimination.

Let's walk through how to diagnose the most common mechanical issues our technicians see every day. We'll cover what to look for and how to test each part safely.

Safety First: Before you even think about opening up the machine, always unplug it from the wall. This is non-negotiable and protects you from serious electrical shock.

Testing the Lid Switch or Door Lock Assembly

Whether you have a top-loader with a lid switch or a front-loader with a door lock, this part serves one crucial safety purpose: it stops the washer from spinning if the door isn’t securely closed. If this switch fails, the washer’s control board never gets the "all-clear" signal it needs to start the high-speed spin cycle.

You might hear a click when you shut the door, but that doesn’t mean the switch is working electronically. It can fail mechanically (the plastic bit breaks) or electrically (the internal contacts are shot).

To know for sure, you’ll need a multimeter set to the continuity setting (it usually has a symbol that looks like a sound wave).

- Find the switch: You’ll have to pop off the top or front panel of the washer to get to it.

- Disconnect the wires: Gently pull the two wires off the switch terminals.

- Test for continuity: Touch one probe of your multimeter to each terminal. With the door closed (or the switch’s button pushed in), the meter should beep or read close to zero. If you get silence or a reading like "OL" (open loop), the switch is broken and needs replacing.

This small, inexpensive part is one of the most frequent culprits we see. It gets used with every single load, so it’s often the first thing to give out.

Inspecting the Drive Belt

The drive belt connects the motor to the drum, turning the motor's power into spinning action. If you can hear the motor humming but the drum isn’t moving, a bad belt is your prime suspect.

Over years of use, these rubber belts can stretch out, get brittle and crack, or just snap altogether. Sometimes, a belt simply slips off the pulleys. You’ll need to take off the back or bottom panel to get a good look at it.

Here are the tell-tale signs of a failed belt:

- Visible Damage: Look for obvious cracks, frayed edges, or shiny, glazed spots.

- Too Much Slack: A good belt should feel taut. If you can easily pull it more than an inch, it’s stretched and can no longer grip the pulleys properly.

- Broken or Slipped: This one’s easy—if the belt is broken or just lying in the bottom of the machine, you've found your problem.

It’s an interesting fact, but our field data shows that drive belt issues account for roughly 70% of all washing machine problems our technicians encounter. It's a staggering number that really shows how often this one component is the root cause of a breakdown.

If your belt looks worn out, replacing it is a must. The good news is that for most DIYers, this is a pretty straightforward and affordable fix.

Checking the Motor Coupler on Direct-Drive Models

Not all washers have belts. Many models, especially from brands like Whirlpool and Kenmore, use a direct-drive system. In these machines, a small plastic-and-rubber part called a motor coupler links the motor right to the transmission.

This coupler is designed to be a weak link. If the tub gets overloaded or the transmission locks up, the coupler breaks apart to protect the much more expensive motor from burning out.

A broken motor coupler has very specific symptoms. You’ll hear the motor running—maybe with a grinding or buzzing noise—but the drum won’t agitate or spin at all. To check it, you’ll have to separate the motor from the transmission. The coupler is a small piece, and if it's failed, you'll see it in broken pieces between the two components.

Examining the Clutch Assembly

Think of the clutch in your washer like the clutch in a car. Its job is to engage slowly and bring the drum up to full spinning speed without a sudden jolt. When the clutch wears down, it can't grip the spin basket tight enough to do its job.

Signs of a failing clutch include:

- The washer spins, but much slower than it used to.

- You smell something burning during the spin cycle.

- The drum seems to struggle to get going or won’t spin at all, even though the motor is running.

- You hear grinding noises as the worn clutch pads slip.

Replacing a clutch is a more advanced repair. It means taking apart a good chunk of the washer's drivetrain and often requires special tools. For more complex repairs like this, you can check out our guide on common washing machine issues and solutions.

When the simple fixes don't do the trick, it's time to dig a bit deeper. If you've already checked the lid switch and the drive belt is in good shape, but your washer is not spinning, the culprit is often hiding one layer down. This part of the guide is for the confident DIYer who's ready to tackle trickier issues, from hidden clogs to the machine's electronic brain.

Before we jump in, a quick word of caution: these next steps involve getting into parts that deal with both water and electricity. Always unplug your washing machine first. It's also a good idea to have a few old towels and a shallow pan handy. Safety first—that's the key to any successful repair.

Investigating Drain Pump and Hose Blockages

Here’s a piece of wisdom from the field: modern washers have a built-in safety check. They refuse to start a high-speed spin cycle until the drum is almost completely empty. If your machine can’t drain properly, it simply won't spin. This smart feature prevents the chaos of a heavy, waterlogged drum trying to spin at high RPMs.

A clog in the drain system is one of the most common reasons a washer gives up on spinning. The blockage could be lurking in the drain pump filter, the pump itself, or the hose leading out of your house.

- Locate and Clean the Pump Filter: Most front-loaders have a little access door on the bottom front corner. Get your pan and towels in position, then slowly unscrew the filter cap. A bit of water will come out, hopefully along with whatever lint, coins, or buttons were causing the problem.

- Inspect the Hoses: Take a look at the corrugated drain hose running from the back of your washer to the wall pipe. Make sure it isn't kinked or crushed. If it looks okay, get a bucket ready, disconnect it, and check both ends for any stubborn blockages.

A surprising number of spin failures are actually drainage failures in disguise. If your clothes are coming out soaking wet and you can still see standing water in the tub, a clogged drain is your most likely suspect.

Cleaning a pump filter is a quick job—often less than 15 minutes—and it can get your machine back in action immediately.

Recognizing a Faulty Drive Motor

The drive motor is the powerhouse of your washing machine, turning the drum for both the wash cycle and the fast spin. These motors are built tough, but they don't last forever. When one starts to fail, it usually gives off specific warning signs.

You might be dealing with a motor issue if you hear a distinct humming or buzzing sound right when the spin cycle should be kicking in, but the drum stays put. In more serious cases, you might smell a burnt, electrical odour—that’s a major red flag telling you to unplug the machine right away.

Another clue is an intermittent spin. The motor might try to start, give the drum a short, weak turn, and then just quit. This often points to overheating or failing internal components. If your washer is flashing an error code, it's trying to tell you what’s wrong. Our guide on how to read Whirlpool washer error codes can help you translate it.

Confirming a bad motor usually requires a multimeter to check for electrical continuity. This is a step best left to those experienced with electrical testing.

The Last Resort: Examining the Control Board

The main control board is your washer’s central command. It takes information from sensors—like the door lock and water level—and tells the motor and pump what to do. When this board goes on the fritz, the whole operation can descend into chaos.

Honestly, diagnosing a bad control board is often a process of elimination. You should only start suspecting the board after you have confidently ruled out every other possible mechanical or electrical part. There's no simple test for it; you usually land on this diagnosis when nothing else makes sense.

That said, a quick visual inspection can sometimes give you a definitive answer. Unplug the machine, access the board, and look closely for:

- Burn Marks: Any black or brown spots on the board or around its components are a dead giveaway of a short circuit.

- Bulging or Leaking Capacitors: Those little cylinder-shaped parts should be perfectly flat on top. If any are bulging or leaking, they’ve failed.

- Corrosion: Check for any greenish or whitish powder on the solder points, which usually means moisture has gotten in.

A faulty control board is a major repair. The part itself can be pricey, and swapping it out involves handling many delicate connections carefully.

It turns out, washer failures are incredibly common. Based on data from over 20,000 service calls, about 21% of homeowners needing appliance help are dealing with a washing machine that has completely stopped working. This just goes to show how often these workhorse machines break down, with spinning and draining issues leading the charge. You can find more insights on common washer problems from Divine.ca.

DIY Vs Professional Washer Repair

Figuring out whether to grab your tools or pick up the phone comes down to the complexity of the job and your own comfort level. To help you make the call, here’s a quick look at some common failures and what they entail.

| Component Failure | Common Symptoms | DIY Difficulty | When to Call a Pro |

|---|---|---|---|

| Drain Pump Clog | Standing water in drum; won't spin. | Easy | If the clog is deep within the internal hoses. |

| Faulty Drive Motor | Humming with no spin; burning smell. | Hard | Always. Motor replacement requires electrical knowledge. |

| Bad Control Board | Erratic behaviour; multiple errors. | Hard | Always. Requires precise diagnosis and handling. |

| Stuck Pressure Switch | Won't spin; thinks tub is full. | Medium | If testing with a multimeter seems too complex. |

While a simple drain clog is a great first DIY repair, issues like a bad motor or a fried control board are complex and carry risks if not handled correctly. For those jobs, bringing in a seasoned professional is the safest and most effective route to getting your laundry day back on track.

Simple Habits To Prevent Future Spin Problems

The best way to fix a washer that won’t spin? Stop the problem from happening in the first place. A little proactive care and a few good habits go a long way in extending your machine's life and saving you the headache of surprise repairs.

These small, consistent actions protect crucial components from unnecessary wear and tear, ensuring your clothes come out perfectly spun every time.

It’s all about making a few small tweaks to your laundry routine. By steering clear of common mistakes, you can keep your washer's motor, drive belt, and other mechanical parts running smoothly for years.

Respect Your Washer's Capacity

One of the quickest ways to trigger spin problems is by consistently cramming too much into the machine. An overstuffed drum forces the motor to work overtime and makes it almost impossible for the load to balance itself out. This puts a massive strain on the drive belt, motor, and suspension.

For the best results, your laundry needs room to tumble freely. A good rule of thumb? Never fill the drum more than three-quarters full. This simple habit not only helps your washer spin properly but also gets your clothes much cleaner.

On the flip side, avoid washing a single, heavy item like a bathmat or a duvet by itself. Always toss in a few smaller items, like towels, to help distribute the weight evenly. This prevents the dreaded off-balance error that stops a cycle cold.

Use the Right Detergent in the Right Amount

More detergent doesn't mean cleaner clothes. In fact, using too much soap—or the wrong kind—can create a mountain of suds that the drain pump can't handle. If a washer can't drain all that soapy water properly, it will often refuse to spin as a safety measure.

Always use a high-efficiency (HE) detergent if you have an HE machine. These formulas are designed to produce fewer suds. Follow the measurement lines on the cap precisely to avoid residue buildup that can clog pumps and hoses over time.

This is a crucial preventative step. To keep your machine in top shape, learning how to clean a washing machine can stop buildup-related issues before they even start.

Ensure Your Machine is Perfectly Level

A wobbly washing machine is a noisy washing machine. If it's not perfectly level, it will vibrate like crazy, especially during the high-speed spin cycle. This constant shaking is more than just an annoyance; it causes premature wear on everything from the suspension springs to the drum bearings.

Grab a carpenter's level and place it on top of your washer. If it’s off-kilter, you’ll need to adjust the machine’s feet until the bubble is perfectly centred. Most washers have adjustable, threaded feet that you can raise or lower with a wrench.

- Front-to-Back: Check the level from the front edge to the back edge.

- Side-to-Side: Do the same, checking from the left edge to the right.

- Final Check: Once it's level, give the machine a push from the corners. It should feel solid and not wobble at all.

Keeping your washer stable is one of the most effective ways to prevent mechanical failures and ensure it can always hit a smooth, powerful spin.

Knowing When To Call a Professional Technician

There's a great sense of accomplishment in fixing your own appliance, but sometimes a repair is best left to the experts. Knowing your limits is a huge part of any successful DIY project, and stepping back at the right time can protect both you and your washing machine from serious damage.

If you’ve gone through all the troubleshooting steps and your washer is still refusing to spin, that’s a clear sign that a more complex issue is at play—one that needs a professional diagnosis.

Clear Signs It Is Time For a Professional

Some problems are immediate red flags that should have you picking up the phone instead of a wrench. Your safety always comes first, so don't take any chances with these.

You should stop what you're doing and call for help if you notice any of these:

- A strong burning smell: The distinct odour of burning plastic is a major warning. This often points to a failing motor, a short-circuiting control board, or an overheating wire—all of which are fire hazards.

- Sparks or smoke: Any visual sign of an electrical malfunction is a non-negotiable reason to call a technician. Unplug the machine immediately and don't plug it back in.

- Loud grinding or metallic screeching: Harsh metal-on-metal sounds can signal a catastrophic failure of internal parts like bearings or the transmission. Pushing it further could destroy the machine entirely.

- Water leaking near electrical components: If you find water pooling around the motor, the main control board, or any wiring, you're looking at a serious shock hazard.

A professional technician isn't just a repair person; they're a safety expert. They have the right diagnostic tools and years of experience to trace the root cause of complex electrical issues, ensuring the repair is done correctly and safely.

The Value Of an Expert Diagnosis

Beyond the immediate safety concerns, calling a professional offers efficiency and peace of mind. Our technicians use specialized diagnostic equipment to pinpoint the exact cause of the failure, which saves you the time, money, and frustration of replacing the wrong parts through trial and error.

We can quickly source the correct, manufacturer-approved parts for your specific model, often having them right in our service vehicle. Perhaps most importantly, our work is guaranteed. A professional repair from us comes with a warranty on both the parts and the labour, so you can be confident the fix will last.

If you’re feeling overwhelmed by a complex repair, learning how to choose the right technician for appliance repair is the best next step you can take.

Had Enough of DIY? Let the Pros Take Over

If you've tried everything and that washing machine still won't spin, don't let the laundry mountain win. When your DIY efforts have hit a dead end, it’s time to call in the experts. At Repair My Appliance, we offer fast, professional service across Calgary, Edmonton, and Red Deer. Our licensed technicians will get to the bottom of the problem and have your machine running again, often on the very first visit.

A truly reliable repair partner isn't just about technical skill; it's about running a tight ship, which is why we follow proven field service management best practices. This approach means your repair is handled smoothly from the moment you call us until the job is done right.

We believe in honest, upfront pricing. Your service call fee is waived with any completed repair, so there are no surprises. Plus, we stand by our work with a solid warranty on both parts and labour, giving you complete peace of mind. Let us restore order to your home with expert help you can actually count on.

Need appliance repair? Visit RepairMyAppliance.ca or call 587-416-5888 for fast, professional service you can trust.

Your Top Questions About Washer Spinning Problems

When your washer won't spin, you've got questions. As technicians, we've heard them all. Here are the answers to the most common queries we get from homeowners, designed to give you clarity and help you figure out your next move.

A question we hear all the time is about clothes being soaking wet after a wash. If you've used a "Delicate" or "Hand Wash" cycle, that's actually normal. Those cycles use a very slow spin on purpose to protect your clothes, which means they'll hold onto a lot more water.

The easy fix? Just run a separate "Drain & Spin" cycle. This almost always solves the problem and doesn't point to a mechanical failure—it's just a settings thing.

Why Did My Washer Stop Right Before the Spin Cycle?

More often than not, a washer that stops just before it's supposed to spin has tripped one of its safety sensors. The number one culprit is an unbalanced load. Think heavy towels or a big comforter all bunched up on one side of the drum.

Modern machines are smart enough to halt the cycle to prevent the violent shaking that could damage the machine itself. The first thing you should always try is opening the lid, redistributing the clothes evenly, and restarting the cycle. Another common reason is a clogged drain pump—the washer won't even try to spin if it can't get rid of the water first.

Is a Washer That's Not Spinning an Expensive Fix?

The cost to fix a washer that won't spin can really vary. It all comes down to what part has failed.

- Inexpensive Fixes: Things like a broken lid switch or a clogged drain pump are usually pretty easy on the wallet.

- Moderate Fixes: If it's a worn-out drive belt or a broken motor coupler, you're looking at a mid-range repair cost.

- Expensive Fixes: The big-ticket items are the main drive motor or the electronic control board. A repair on one of these can sometimes cost nearly half as much as a new machine.

Getting an expert diagnosis is the key to not overspending. A technician can pinpoint the exact issue, so you don't waste money replacing parts that are still perfectly fine.

Can I Just Reset My Washing Machine to Fix a Spin Problem?

Yes, and you should definitely try this first! A simple hard reset can often clear up minor electronic glitches that are preventing the spin cycle. To do it, just unplug the washer from the wall outlet and leave it for at least five full minutes.

This gives the internal capacitors on the control board enough time to fully discharge, which clears out any temporary software errors. After the five minutes are up, plug it back in and try to run a spin cycle. You’d be surprised how often this simple trick works for those intermittent problems. For those who want to dig deeper into the workings of the Appliance Repair industry, there are great resources available that provide a broader context.

Need appliance repair? Visit RepairMyAppliance.ca or call 587-416-5888 for fast, professional service.